2012 Update! I cracked this bulkhead in about 25 hours.. Screw it, I’m going carbon. Check back for my entire spinner, bulkhead, everything turning in the front upgrade.

The main spinner bulkhead has long been a weak link with Lancair aircraft. I had read about cracks in the bulkhead from other Lancair owners on the LML. Most experienced cracks every 300-500 hours of operation. During my next annual condition inspection, I found cracks at all 4 mounting bolts of my bulkhead. I called Lancair to order a new bulkhead only to find out they were on backorder for 6 weeks. Thanks to a fellow LNC2 owner, he hooked me up with his spare and I got to work.

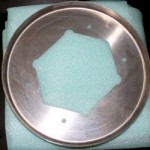

First, the spinner came with 4 plates that were to be riveted to the bulkhead. These plates were to reinforce the mounting bolts that go through the prop hub. Most cracks were found around these plates. My plan was to eliminate the 4 plates and create a “doubler” for the entire bulkhead essentially doubling the thickness of the bulkhead.

Once the “doubler” was completed I riveted it to the main bulkhead with the help of a local RV-8 builder. Figured those guys would know aluminum, and that has proven to be true. Then was the long process of adding the 1.2 million nut plates for the spinner screws. Not sure what the original builder was thinking, the spinner would be just find with about half as many screws I think. But, when in Rome…

UPDATE! Turns out, .040 wasn’t enough. This bulkhead doubler cracked also. Fortunatly, it saved the original bulkhead (the expensive part) from cracking. I removed the prop, removed the spinner bulkhead, and drilled out the rivits for my original doubler. I then made a new doubler off of a template from the old. This time I used 2024 T3 aluminum .080 thick. This is the same thickness as the original bulkhead material. Also, before I rivited the bulkhead in place, I put a small bead of silicone around the outside edge of the doubler. The idea is, if there were to be any vibration from this part, the silicone would dampen that, and hopefully prevent cracking.

Also, just FYI.. This original doubler lasted 240 hours. But, 1 week at Reno running 3000 RPM cracked it. There are some pretty amazing vibrations going on at that RPM it seems.

I developed tooling and have been making fiberglass spinner bulkheads to replace those on lancair 320/360 aircraft. Email me back if you’re interested in more info.

Chris

Man, wish I had known that a few weeks ago… Do you also have a forward bulkhead? Send me some info and I can put up a post here to maybe get you some business, and save others the trouble I have had..

hello

i am interested about jour bulkeads, woul jou send me picture price and time to delyvrery

hartzell 2 blade,

best regards michel hambursin

Hi Michel, If you’re still interested in a fiberglass bulkhead I can have one ready to send to you in a few days. email me at x24thepilot@hotmail.com for further info and pics.

Thanks,

Chris