During a test flight of the airplane while preparing for the Reno Air Races it developed a problem with the landing gear. The worst part about this problem is that it was random. That always makes finding the problem much harder to do. So, here is what happened.

During a preflight I noticed that the right main over center spring was not seated on the over center link itself. The spring had somehow come off and hooked the top of the link, not around it as the spring is designed. Now, 320/360’s have 2 different types of over center springs.

The “rat trap” springs as they are referred to are most common. These springs are a coil type spring that wraps around the bolt connecting the over center link to the main gear leg. From that bolt an arm of the spring extends out and hooks over the over center link itself, pushing the link down and locking the gear in place.

The other type of spring looks like something found on a screen door to your house. A long spring that attaches at both ends, pulling the two points to the center of the spring. This spring connects at the center of the over center link and the bottom of the gear leg itself. Thus, pulling the over center link down locking it in place. A simple design.

Fortunately for me, my airplane has both springs. During each annual inspection a gear freefall test has always been completed, and the airplane has always passed with only a small amount of pull to get the mains to lock in place. This is accomplished in flight by yawing the airplane and using the relative wind to push the mains out and lock them. Locking the mains in this fashion is acceptable by the Lancair POH. Now, back to the story..

The “rat trap” spring was not seated on the over center link during preflight. With a small nudge the spring snapped back over the link into it’s normal position. Being that having working landing gear is sort of a big deal, I elected to solve the problem. Once the aircraft was up on jacks we performed 5 or 6 gear swings with no trouble, and successful emergency extensions. The over center spring always ended up in the correct position, and the gear had no sign of trouble. Hmmmm The next step was to disconnect the gear doors and see what things look like when the gear is retracted. And now for the real surprise.

With the gear retracted, the spring had 0 pressure to hold it in place. The spring was completely shot. But more interesting, what masked this problem is the fact I have the second form of over center springs that were working just fine, and they were replaced not long after I purchased the airplane, just to be safe. During the gear testing on the ground the spring always came down in the same place. I assume that is because the airplane was still, not bouncing around like it would in flight. Again, masking the problem.

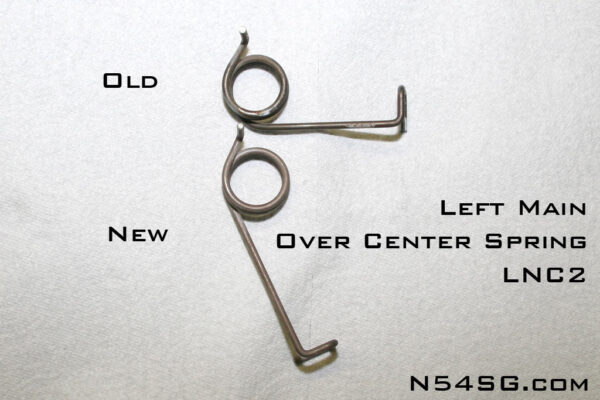

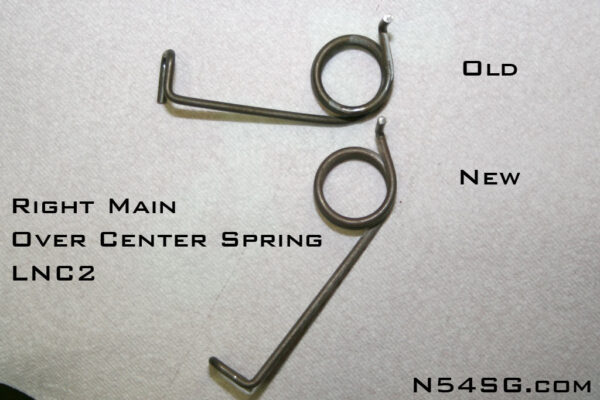

So, I ordered up a pair of new springs from Lancair and I got some great shots to compare the old to the new springs. For reference, the old springs are probably the original supplied with the kit. Probably 15 years old and 700ish airframe hours. Moral of the story, springs get old.

Where can I get these new style springs and what is the Cost ?

Thank you

Kevin

505-450-4401

New springs came direct from Lancair. $35 each if I remember correctly.

Tom

Thanks for the heads up! It’s amazing how many little maintenance items can escape you. Nice find and thanks for sharing!!!

Thanks, I’ll be adding more soon. Doing a big firewall forward rehab so lots of fun stuff to add when I get finished.

Lancair had a batch of bad springs back in the mid-nineties. Don’t recall the details, but you may have just found one of them.