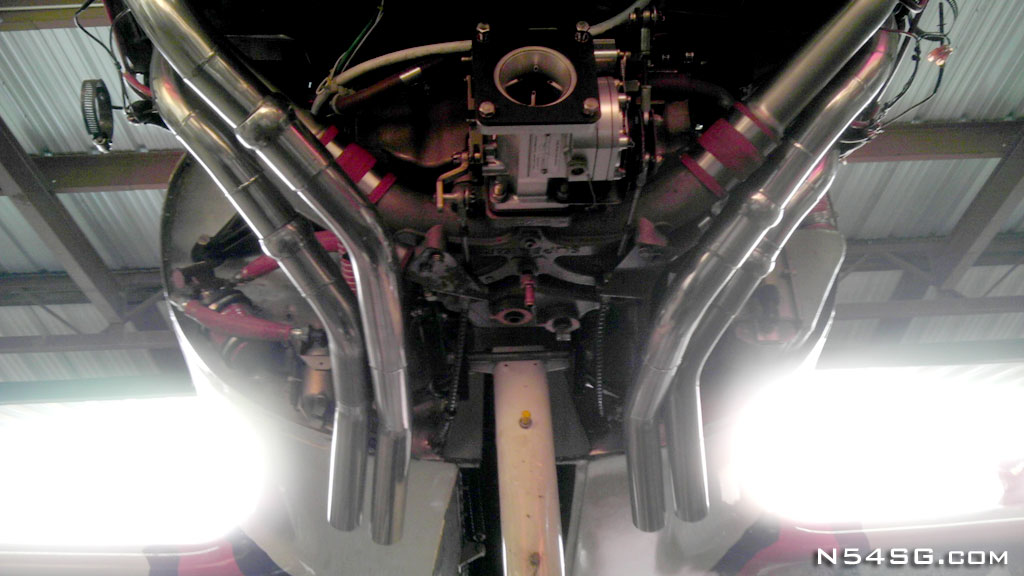

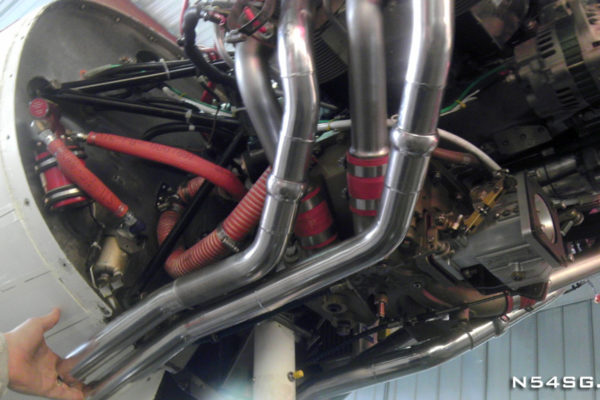

The problem isn’t the exhaust itself, matter of fact it has been (one of the few things) trouble free. The issue I have is the huge amount of space it takes in the cowling, primarily the crossover pipes below the intake. These 2 pipes, cylinders 1 and 3, have to cross over to the collector on the pilots side of the airplane. This ruins any chance for a good looking cowling and a less than ideal aerodynamic shape. Now don’t forget, this is an angle valve engine in a cowl designed for a parallel valve engine that is more narrow and not as tall. So this big header just makes it worse. Old system pics:

I know I know, from a horsepower standpoint, 4 into 1 is the best. So that makes this decision that much harder. The next best system for power is 4 individual pipes. That also works well for my space restrictions. Each side with have two pipes exiting, so I decided to make what I call “ramps” or “exhaust tunnels” down the bottom of the cowl. This makes room for the pipes and makes the curve as gentle as possible. More on the cowling in a different update.

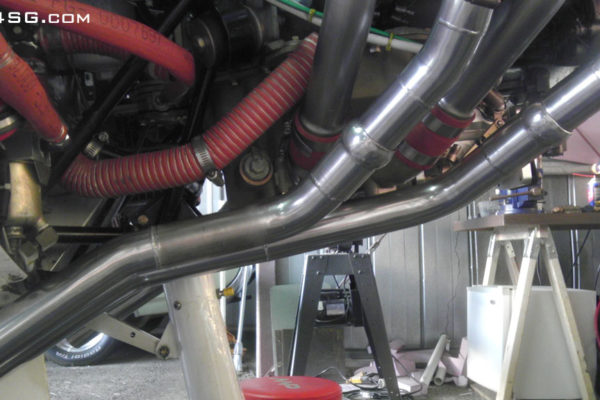

I called around looking for an off the shelf system, and couldn’t find one. Imagine that. Having a custom system made also had a wide variety in cost and build process. In the end, I went with Sonic Headers. I got their “PVC Kit” and got to work. For a deposit, they send flanges that bold to your exhaust ports that are sized for 1 1/2″ Schedule 40 PVC pipe. A quick stop to Home Depot netted a bag full of elbows and some pipe.

I lost count of how many times I just took it off and started over. You think your headed in the right direction, only to expose a new issue. Don’t screw or glue anything till your done with all 4 pipes. Once I had them where I thought it was all going to work, I screwed each section together and shipped them to the welder.

It took a bit longer than I had wanted, but what I got back was great! I had them ceramic coated as well, so not only do they look great they should perform better as well.

Hangers, damn hangers. There are a lot of opinions about hangers. I am of the opinion that a moving engine, and a fixed hanger (firewall) is a bad mix. In theory, if your hanger was on the engine, and moved with it, you would be in good shape. So once I had the exhaust, I used wood dowel rod to simulate 4130 steel tube. I trimmed them to shape and then matched the wood with steel. Carefully I tack welded the brackets in place, on the engine. Then removed them for final welding and paint.

UPDATE

Reno taught me a lot about exhaust brackets, as I broke mine all to hell. The general consensus from those that know what they’re doing (the Steadfast Unlimited Team) is that I was on the right track, but made them too stiff. What I didn’t account for was the system growing in length. Also that I am not a welder, and shouldn’t pretend to be one. A later version will have a long curve, and welded by a professional.

Everyone on the ground says they sound pretty awesome, so that is a bonus!